Mesin Cutting Laser Metal Serat Cilik Kanggo Pipa

| Jinis | TKF-T-1500W |

| daya laser | 1500W |

| Media laser | YVO4 |

| Panjang gelombang laser | 1070nm |

| Min.baris | ≤0.15mm |

| Maks.kacepetan Range | 30 ~ 50m / min |

| Maks.Perjalanan sumbu Y | 500~1000mm |

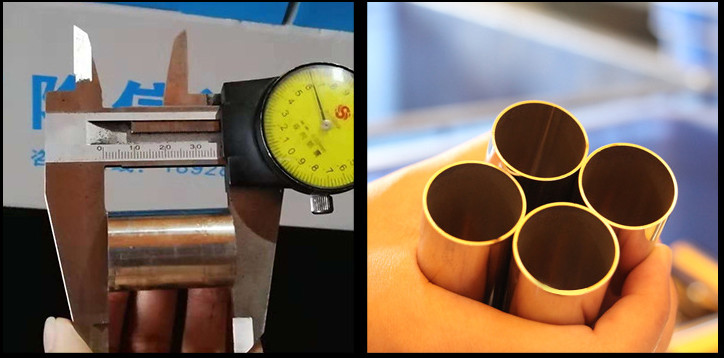

| Maks.Area pemotongan tabung bunder | ф50 ~ ф100 mm |

| Akurasi posisi aksial saka bangku | ≤±0,03㎜/m |

| bench bola akurasi posisi | ≤±0,03㎜/m |

| Range pemotongan ketebalan stainless steel 304 | 0,5--4 mm |

| syarat sumber daya | 380V/50HZ |

| Total tingkat proteksi sumber daya | IP54 |

| Kapasitas dipasang mesin | 18KVA |

| Num. | Konfigurasi utama | isi | pabrikan |

| 1 | Laser | ● serat laser | Mac.Ing Shen Zhen |

| 2 | mesin kontrol industri | ● CPU I5 ● Fungsi grafis ● panyimpenan 8G ● Antarmuka komunikasi komputer, Ethernet, antarmuka USB, lsp ● hard disk 256G ● sistem operasi WINDOWS 10 ● LCD | selaras dening Techkey Laser |

| 3 | Komposisi sistem pneumatik | ● klep elektromagnetik | SMC Jepang |

| 4 | Komposisi sistem transmisi | ● Rel guide garis lurus kanthi tliti dhuwur | Taiwan HIWIN |

| ● motor servo lan driver | Panosonic Jepang | ||

| 5 | Motong sirah lan komposisi sistem pelacak vertikal kapasitif | ● sirah nglereni serat | merek Swiss |

| ● transduser kapasitif● amplifier (inset)● kothak luwes | Shanghai kanca | ||

| 6 | Komposisi sistem kelistrikan | ● kontaktor | Schneider saka Prancis |

| ● ngalih fotolistrik | Omron ing Jepang | ||

| ● terminal | Jerman weidmuller | ||

| ● Rantai tank | Cangzhou, Hebei | ||

| 7 | Piranti lunak | ●CypCut LaserCut | Shanghai, kanca |

| 8 | Sistem pendinginan | ● cooler profesional | KSTAR |

| 9 | Kabinet pipa pemotong khusus | Customized dening Techkey Laser | |

| 10 | Pipa pemotong khusus | Customized dening Techkey Laser | |

| 11 | Rega | Kalebu rega PPN 13%. | 178000¥ |

1 Kanthi sirah nglereni Brand, nglereni tliti dhuwur

Struktur internal saka sirah laser wis rampung nutup, kang bisa nyegah bagean optik saka rereged dening bledug.

2 Area buta cilik kanggo tailing, nyimpen bahan

Cara dipakani prasaja mbisakake mesin kanggo biasane Cut buntut ≤100mm, kang adoh luwih murah tinimbang Nilai pasar buntut saka 220-300mm, nyimpen mundhut materi domestik lan mbusak proses Processing tailings.

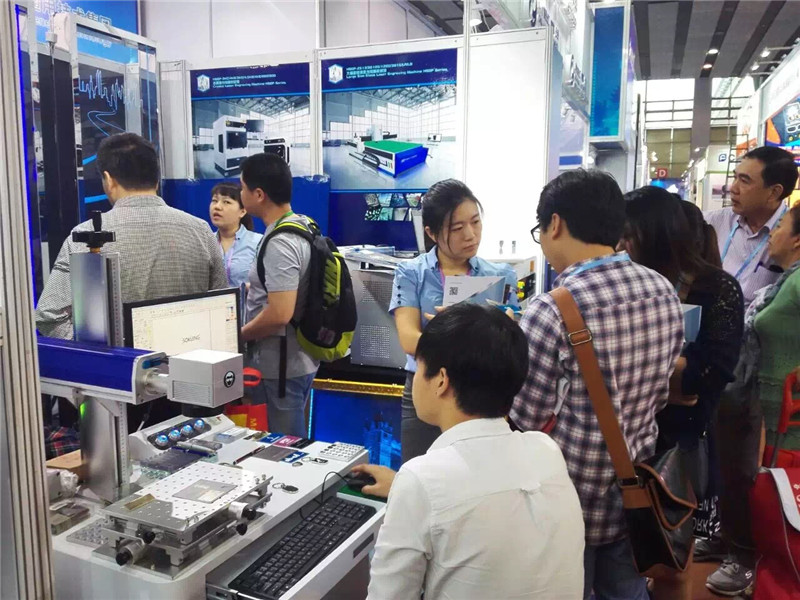

Mesin Laser Marking

Area Mesin Laser 3D

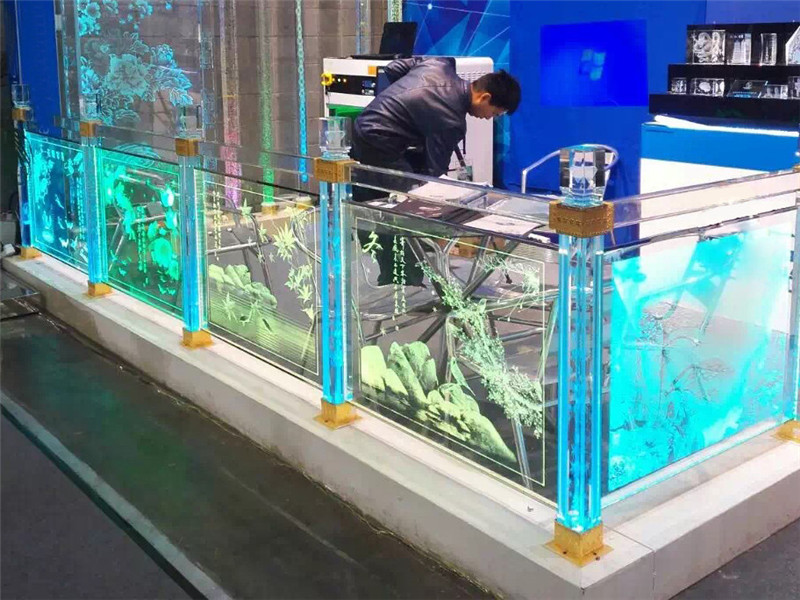

Pengukir Bawah Permukaan Kaca Ukuran L

Pengukir Bawah Permukaan Kaca Ukuran L

Mesin Potong Pipa Kab

Mesin Cutting

Gedung Pabrik

Kategori produk

-

Telpon

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Ndhuwur